Top Medical Robotics Engineers Share 5 Key Lessons

Whether you're a seasoned veteran or just getting started, if you're curious about the world of medical robotics—how it got here and where it's going—you've come to the right place. Coming straight from our visit to IROS—the IEEE/RSJ International Conference on Intelligent Robots and Systems—one of the major robotics conferences alongside ICRA and RSS, we've distilled decades of knowledge and expertise in medical robotics. Here are the Top 5 lessons and advice for long term success and fulfillment in your robotics career.

Robotics is a remarkable part of modern discourse: All at once, it exists as routine machinery, a grounded engineering discipline, a conceptual field of study, and in the public imagination.

The domain is rich with both past successes and future opportunities.

This article highlights the prevailing lessons learned from designing robotic systems, focusing on experiences from the most recent 10–15 years and calibrating them across a diverse backdrop of research, startups, large corporations, and government.

We discuss trends and challenges that influence design and extrapolate potential directions for integrating robots into everyday activities.

#1: Robotics means different things to different people

It's an umbrella term. It's an overloaded term.

Robotics is a wide ranging phenomenon that spans fiction and reality; performs both behind-the-scenes and high profile work; and embodies a society's hopes for a progressive future and fears of a dystopian one.

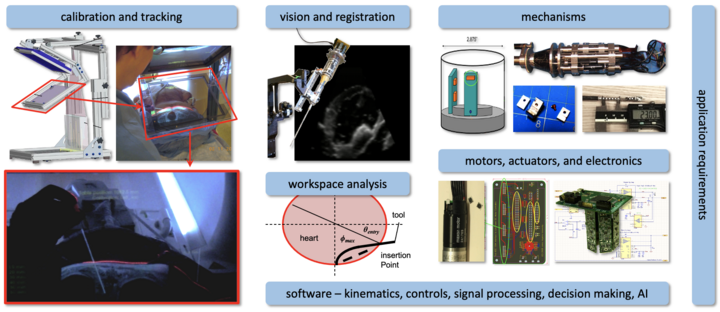

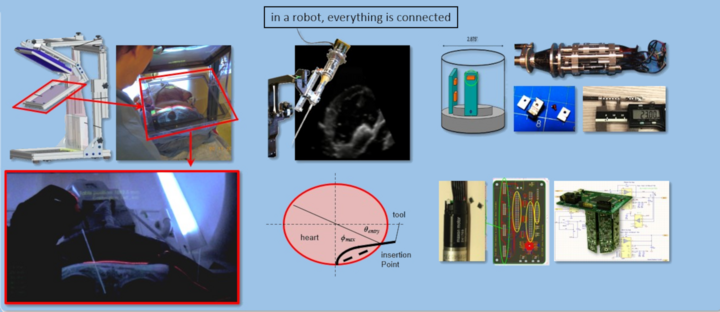

This range of possibilities can be credited to a diverse blend of advanced technologies, including mechanisms, sensors, actuators, electronics, and software, itself an interplay of kinematics, controls, signal processing, and decision making algorithms that govern how the robot engages with its surroundings.

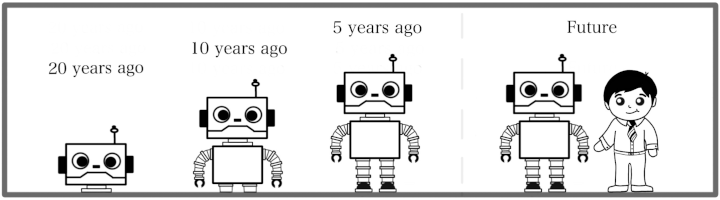

Progress in any area fuels the ongoing evolution in robotics, which in recent years has been further accelerated by artificial intelligence.

Complexity is a recurring theme in robotics, and as we discuss below, it is the source of diverse capabilities, the driver of design practices, and the root of many challenges one encounters in the field.

Video [UPDATED]—A mini autonomous surgical robot captures a moving target in a beating heart phantom under 3D ultrasound guidance. Building on the shoulders of giants, the project spans engineering [biomedical, mechanical, electrical, computer, software, ...], surgery, medical imaging, computer vision, and involves clinicians, hospitals, and healthcare.

#2: Robotics engineering is an unwieldy technical discipline

a. Managing complexity

A robot in the abstract is a union of multiple technologies that coordinate as a single unit. The sub-units of a robot are often full fledged projects in their own right, engineered and managed by domain specialists who in parallel coordinate with specialists of adjacent domains. (Check out The Mythical Man-Month for insights on large engineering projects.)

Numerous engineering challenges commonly arise during robotics development.

Systems contain many thousands of interconnected components, so unexpected behavior is often coupled and difficult to isolate.

For example, a problem that manifests as errant robot behavior may originate from any number of causes, such as an error in the model, a bug in its software implementation, or a faulty component.

Very often, the picture is far more complicated: multiple bugs rather than one, a bad chip that functions correctly when probed, or in at least one author's experience, an intermittently diminished voltage caused by a broken encoder elsewhere in the system.

Such problems can prove vexing because initial instincts fixate on obvious causes, biased by one's expertise. Roboticists have thus developed practices to mitigate these obstacles:

- Keeping it simple: Complexity arises naturally, so the simplest feasible design choices are often preferred. Einstein believed "everything should be made as simple as possible, but no simpler." Who are we to doubt him?

- Diligent unit testing: Regular unit, component, and system testing can catch the side effects of development before they become obscured by continued development.

- Design optimization: Casting a design decision as an optimization problem can help when there are more parameters than can be analyzed cognitively in one's own head.

- Change control: As a system grows in complexity towards production, further changes should be made judiciously.

- Document control: With many consequential decisions being made, records describing the designs and the tests that inform them are valuable for auditing and future reference.

Practitioners may recognize many of these strategies as so vital as to be enshrined in formal processes and, in certain industries, regulation.

Researchers may be familiar with an analogous mindset: meticulously constructing experiments to isolate controls and variables of interest.

Complex, tight component relationships make engineering robotic systems inertial; like steering a ship, early decisions prescribe the course a robot can later take. Changing course can be arduous, costly, or outright infeasible, so roboticists use several strategies for making suitable decisions earlier.

Simulation is a valuable tool for informing design decisions ahead of costly engineering. Pencil and paper are unsung yet useful resources for estimating the feasibility of concepts. The transfer of ideas onto paper helps one build sufficient understanding to effectively use advanced simulators. Proper modeling is critical for filling gaps, optimizing designs, and evaluating performance. Finally, physical prototypes help highlight spatial relationships that are difficult to capture in silico and they may yield reusable fixtures for testing.

Prior experience in design and manufacturing is another valuable resource that helps mitigate costly errors. Individuals often struggle to make complex decisions analytically, so informed foresight on parts such as sensors and software can broaden the limits of the robot, facilitate efficient design iteration and system integration, and ultimately optimize the use of time and resources.

#3: Robotics is both individual and collaborative

Contemporary robotics efforts call for large teams with a diverse set of skills and knowledge. Contrary to popular beliefs around the solitary nature of engineering, work in robotics entails a rich individual and collaborative experience.

a. Beyond the technical skills

Where the wisdom "missing the forest for the trees" stresses the importance of the big picture over fine details, robotics values not just attention throughout the spectrum but cognizance of the spectrum itself. A stream of challenges ranging from obscure bugs to existential questions ("does our robot really help its intended beneficiaries?") is a hallmark of robotics, so working respectfully with others can help resolve complexities at different scales. Joint problem solving can indeed be framed as a source of fulfillment.

b. Potential for extensive impact

Robotics is broadly inspiring, thriving in fiction, fantasy, and reality. The field often motivates mission oriented tech-inclined individuals towards efforts such as COVID-19 safety, search and rescue, injury prevention and rehabilitation, healthcare, and elderly care. In the course of helping society, roboticists first help each other; they often are, or later become, renowned experts in the field (in other words, you get to work with incredible people). Furthermore, the technologies engineers create for the task at hand are sometimes offered to future engineers as open source—the next section explores the potential ramifications of this practice.

#4: Transitioning from systems-centric to situation-aware

a. Today's challenges in robotics

Industrial robots in manufacturing, airplanes, and the Mars Rovers are just a few of many phenomenal robotics successes. Such achievements have arguably altered the fabric of modern society; yet they operate in specialized environments, whereas the penetration of robotics into unstructured environments remains modest. Activities that may benefit from a robot may be more nuanced than expected, making mainstream robotic assistance elusive once development overhead is considered.

b. Technology trends to watch

Much like the obscure encoder bug, the factors preventing robotics from thriving in unstructured environments may be compound and layered. But advancements in technology may eventually alter the cost thresholds enough to make everyday robots viable. Ongoing trends that can potentially help reduce engineering overhead and fuel new opportunities include:

- Moore's Law: Reductions in size/cost of computing and electronics, further allowing use of high level languages such as Python

- Open source: Community software efforts providing sophisticated, pre-engineered functionality (e.g., ROS)

- Off-the-shelf: General purpose manipulators built and shipped with simple APIs, such as KUKA and Universal Robots

- AI/ML + materials: AI models that compensate for the imperfections of low-cost mechanisms, and for the challenges of training a robot's skills explicitly

- UI/UX: Advancements in user interface design for robotics

#5: Key takeaways

The rise of user interface and user experience (UI/UX) professions in the software realm signals the importance of understanding user tasks and flows. It is a harbinger for similar needs in robotics because making machines operate in unison with social dynamics has proven to be nontrivial. Developing insights on people's needs can require diligent anthropological fieldwork, especially where skills are subconscious processes that are difficult to articulate. Undervaluing such nontechnical efforts, however, can incur a "usability debt" wherein a new robot enjoys less impact than projected.

The technological trends listed in above collectively support abstraction, which lets system designers concentrate more on a prospective robot's operational life in its home than on its creation in the lab. Focusing on the intricacies of how a new robot should fit can yield unforeseen insights; in surgical robotics, for example, clinicians may register medical imaging to a robot. A systems oriented view takes this step for granted, whereas a user centric approach examines whether this added burden on clinicians can be alleviated, considering the gravity of their broader responsibilities.

Under-appreciation of clinicians' viewpoints, on the other hand, can be tragic: they often view technology as imperfect and contributing to an epidemic of burnout. A focus on situations can help reveal the value of and need for a robot in the context of alternative, possibly non-robotic, solutions. For example, a more simplified technology for surgery is possible based on an understanding of mental processes during surgical routines.

Robotics covers a lot of different areas, so if it turns out not to be your cup of tea, there are lots of ways for your skills to transfer!

This article was brought to you by P. Thienphrapa, C. Lundin, X. He, M.Y. Jung, P. U-Thainual, and C. Kung and appeared at the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) Workshop on Mechanisms and Design.

Related reading

- Healthcare 2.0: How Robotics and AI are Revolutionizing Clinical Workflows

- 10 Interesting Facts about the da Vinci Research Kit (dVRK)

- The Making of the da Vinci Research Kit (dVRK)